Collection: Printer 3D

A 3D printer is a revolutionary device that transforms digital designs into tangible, three-dimensional objects. Here's a general description:

Core Concept:

-

3D printing, also known as additive manufacturing, builds objects layer by layer from a digital 3D model. This contrasts with traditional manufacturing, which often involves cutting away material.

How it Works:

-

The process begins with a digital 3D design, typically created using computer-aided design (CAD) software.

-

This design is then "sliced" into numerous thin cross-sectional layers by specialized software.

-

The 3D printer then deposits material—such as plastic, resin, metal, or even food—layer by layer, following the instructions from the sliced digital model.

-

These layers bond together, gradually forming the final 3D object.

Types of 3D Printing:

-

Fused Deposition Modelling (FDM):

-

This is the most common type, where thermoplastic filament is melted and extruded through a nozzle to build the object.

-

This is the most common type, where thermoplastic filament is melted and extruded through a nozzle to build the object.

-

Stereolithography (SLA):

-

This uses a laser to cure liquid resin into hardened layers.

-

This uses a laser to cure liquid resin into hardened layers.

-

Selective Laser Sintering (SLS):

-

This uses a laser to fuse powdered materials, such as nylon or metal.

-

This uses a laser to fuse powdered materials, such as nylon or metal.

Applications:

- 3D printing has a wide range of applications, including:

-

Prototyping and product development.

-

Manufacturing custom parts and tools.

-

Creating medical implants and prosthetics.

-

Architectural modelling.

- Art and design.

- Educational purposes.

-

Prototyping and product development.

Key Advantages:

-

Enables the creation of complex geometries that are difficult or impossible to produce with traditional methods.

-

Allows for rapid prototyping and on-demand manufacturing.

-

Reduces material waste.

-

Opens up possibilities for customization and personalization.

In essence, a 3D printer is a versatile tool that empowers individuals and industries to bring their ideas to life in a physical form.

-

Creality CR-10S 3D Printer V1 – Large Build Volume, Reliable and Easy to Use

Regular price £150.00 GBPRegular priceUnit price / per -

Sold out

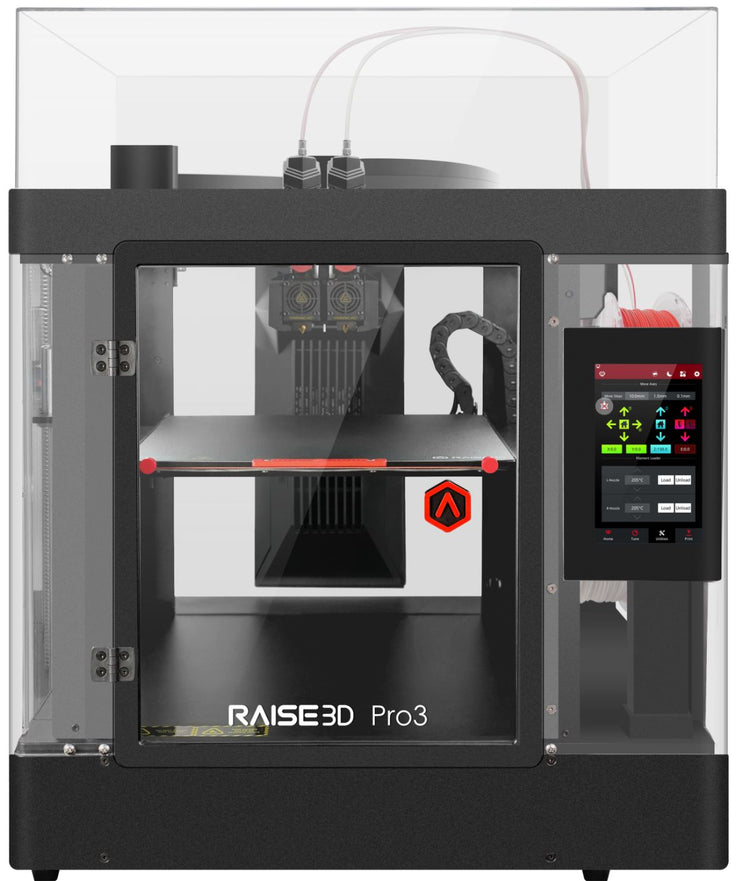

Sold outRaise3D Pro3 3D Printer New

Regular price £2,500.00 GBPRegular priceUnit price / per -

Creality CR20 Pro 3D Printer – New Open Box – Reliable, Compact, Easy to Use

Regular price £150.00 GBPRegular priceUnit price / per